Electrically Automated Guided Vehicles (AGV’s) are becoming increasingly common, as many manufacturers look to reduce their carbon footprint with equipment that simply plugs in. It’s best to invest in automation progressively, tackling each section of your warehouse independently. This ensures ample time to modify operations, complete safety training to prevent workplace injuries, and budget accordingly. Here are a few things to keep in mind when optimizing your business in 2022.

Step 1: Upgrade Hydraulic Equipment

More industry giants are ditching hydraulic battery changers for their higher maintenance needs and upgrading to electrically powered equipment for improved performance and programmable options. This inevitably raises concerns about energy consumption, cost-efficiency and design.

That’s where we come in to answer all your questions about changing, charging and managing your forklift fleet with electrically powered battery handling equipment in your warehouse. Our first piece of advice, upgrade your hydraulic equipment; it isn’t cost-effective or environmentally friendly. Here are some fun facts to get you started on your journey to an all-electric battery room that Elon Musk would applaud.

Step 2: Channel Elon Musk

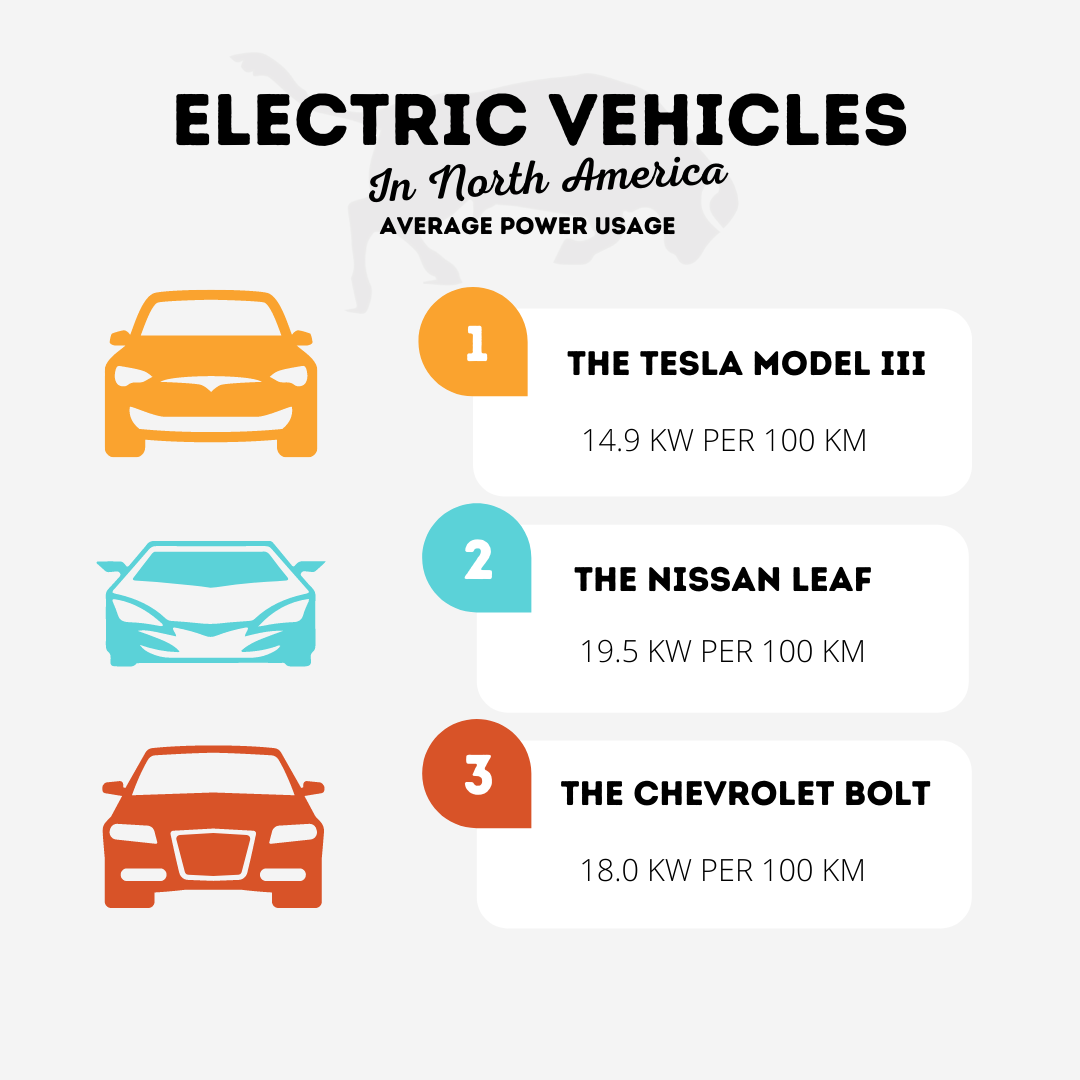

To put the following stats into perspective, three of the top-rated electric vehicles in North America (according to Car & Driver) consume an average of 17.4 kilowatts per 100 km driven.

This recently installed Carney Battery Bull Electric (BBE) exchange system has the daily capacity to accept and discharge an average of 3,400 Kilowatts of stored electrical energy per day. Transferring an average of 1.2 Gigawatts of power per year to support an entire fleet of electric forklifts. This is enough to power 225 Teslas per day for a distance of 100kms! Fascinating, we know. Think of investing in your battery room the same way you would a Tesla; an electric battery changer is quieter, has more features and requires less maintenance.

Step 3: Conquer Battery Handling First

Your forklift fleet is what powers your operation; ensuring every forklift is changed, charged and ready for action is optimization in and of itself. So, start there.

In 2018, Material handling publications projected that an average of fifty-two percent of warehouses would invest in automation and distribution in coming years. As we dive into 2022, the demand for efficient material handling equipment continues to rise. Businesses everywhere are taking advantage of the emerging advancements in electric fleet management that offer warehouses longer runtimes, fast charging and hassle-free maintenance.

As renewable energy becomes more available, industrial companies, large retail operations and manufacturers can reduce their carbon footprint capturing cost savings by simply electrifying their operation. A surprising 80% of fulfillment warehouses have yet to automate most of their processes, overwhelmed by the plethora of choices that automation presents. A simple equipment upgrade, like designing an all-electric battery room, investing in a fully automated all-electric battery changer or optimizing with a park & charge system, can affordably conquer your battery handling requirements as you strategize improvements for the rest of your warehouse.

The point is that electric material handling can be a reasonable first step to a fully automated warehouse and presents benefits to every company regardless of size. Much like the vision that founded Tesla in 2003, CBH strives to conquer battery handling by proving that you don’t need to compromise to go electric.

Products To Get You Started

The Battery Bull Electric - Fully Automated

Powerful, compact and energy-efficient PLC controlled Variable Frequency Drives (VFD) are coupled with electric gearboxes to provide simultaneous power to lift and drive functions. The BBE is one of the few high-volume fully electric transfer carts options and can be completely automated.

The Universal Tugger

The latest addition to our globally recognized BTE series, the UNI-Tugger lowers the risk of material damage and reduces strain on employees, ultimately improving productivity and streamlining changes.

Park & Charge Stands

Carney Battery Handling offers a wide range of park and charge stands to suit multiple charger configurations suited to various facility layouts. Our opportunity charging stations and floor mount charger shelves can be completely customized for various widths, heights and shelves and shelf configurations.