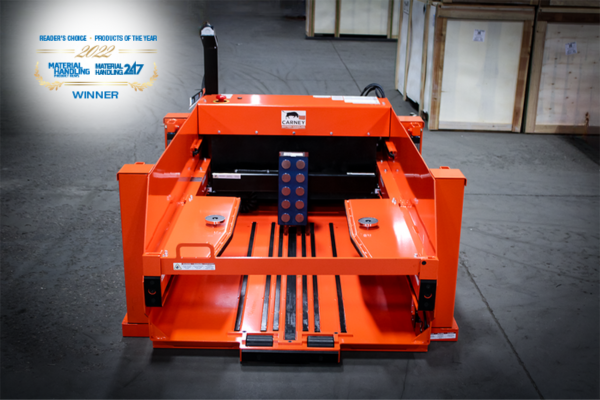

UNI-TUGGER

Battery Bull Electric – Fully Automated

Elected product of the year in 2022, our universal tugger comes equipped with a linear actuator system, a powerful electromagnet, and accommodations for various roll-off heights. Adaptable to your operational needs, the UNI-Tugger is outfitted with logical controls for efficient changing and is finished in an acid-resistant powder coating to withstand harsh conditions.

The latest addition to our globally recognized BTE series, the UNI-Tugger lowers the risk of material damage and reduces strain on employees, ultimately improving productivity and streamlining changes.

- Finished in acid-resistant powder coating

- Integrated lift using linear actuator system

- Simple and logical controls

- 5-year magnet warranty

- Accommodates a range of roll-out heights

- Up to 5,000 lbs battery capacity (depending on host truck capacity)

OPTIONS:

- Custom colour options

- Variable speed and emergency stop controls

- Fold-down battery guides

- Front safety gate

- 10-pole magnet for batteries over 3,530 lbs

BTE

Battery TUGGER

CBH’s Battery Tugger are the global standard in low-volume high-efficiency battery changing. The reliability, safety standards and changing efficiency are second-to-none and unrivaled in today’s battery changing industry. All BTE models are engineered with a fully welded, unibody construction and finished in premium acid-proof powder coat paint to ensure they’ll be delivering reliable and effective battery changes for many years to come.

The BTE series is fitted with our reliable 1,800 lbs electromagnetic extraction system that is used extensively on our man-aboard systems. The unit also uses a lead roller to ensure smooth and damage-free exchanges each time and offers optional battery guides to prevent smaller pallet truck batteries from tipping over.

- Up to 5,000 lbs battery capacity (depending on host truck capacity)

- Powerful 1,800 lbs electromagnet extraction for safe, quick and reliable changes

- Forward and reverse travel limits switches allow less stress on equipment

- Lead rollers to smooth roll-out transition and reduce stress and damage to vital components

- Pendant with variable speed joystick to provide user-friendly operation

- Battery guides to prevent smaller pallet truck batteries from tipping over

- Automatic time-out on magnet ensures long service life and protects against excess discharge on host truck battery

- Available in 12V,24V, 36V, 48V & 80V configurations to suit common host truck applications

- Wide range of standard widths (24”, 30” 36” 42” & 48”) ensure a perfect fit for your battery fleet

- Built to last with solid-welded unibody construction and finished in acid-resistant powder coat paint

- 5-year warranty on magnet

OPTIONS:

- Available in 12V, 24V, 36V, 48V & 80V configurations (24-volt standard)

- Flexible host truck mounting options including a modification-free option

- Variety of widths, lengths and stepped models (see BTSE) to increase flexibility further

- Aluminum drop-in beds available for custom batteries roll-out height

- Pendant and joystick controls to suit different host trucks and operations

- Optional battery guides to allow for handling of narrow batteries safely

- 10-pole magnet for batteries over 3,530 lbs

BTE

Battery TUGGER

CBH’s Battery Tugger are the global standard in low-volume high-efficiency battery changing. The reliability, safety standards and changing efficiency are second-to-none and unrivaled in today’s battery changing industry. All BTE models are engineered with a fully welded, unibody construction and finished in premium acid-proof powder coat paint to ensure they’ll be delivering reliable and effective battery changes for many years to come.

The BTE series is fitted with our reliable 1,800 lbs electromagnetic extraction system that is used extensively on our man-aboard systems. The unit also uses a lead roller to ensure smooth and damage-free exchanges each time and offers optional battery guides to prevent smaller pallet truck batteries from tipping over.

-

- Up to 5,000 lbs battery capacity (depending on host truck capacity)

- Powerful 1,800 lbs electromagnet extraction for safe, quick and reliable changes

- Forward and reverse travel limits switches allow less stress on equipment

- Lead rollers to smooth roll-out transition and reduce stress and damage to vital components

- Pendant with variable speed joystick to provide user-friendly operation

- Battery guides to prevent smaller pallet truck batteries from tipping over

- Automatic time-out on magnet ensures long service life and protects against excess discharge on host truck battery

- Available in 12V,24V, 36V, 48V & 80V configurations to suit common host truck applications

- Wide range of standard widths (24”, 30” 36” 42” & 48”) ensure a perfect fit for your battery fleet

- Built to last with solid-welded unibody construction and finished in acid-resistant powder coat paint

- 5-year warranty on magnet

OPTIONS:

- Available in 12V, 24V, 36V, 48V & 80V configurations (24-volt standard)

- Flexible host truck mounting options including a modification-free option

- Variety of widths, lengths and stepped models (see BTSE) to increase flexibility further

- Aluminum drop-in beds available for custom batteries roll-out height

- Pendant and joystick controls to suit different host trucks and operations

- Optional battery guides to allow for handling of narrow batteries safely

- 10-pole magnet for batteries over 3,530 lbs

BTM

BATTERY TUGGER MANUAL

The BTM series has been specifically designed to remove batteries from lift trucks for servicing and preventative maintenance or to change out batteries when necessary.

Inspired by the hand pallet truck design, the BTM has been expertly engineered to operate identically to a hand pallet truck and utilizes an optional braking system that allows for zero pushback during the battery change. With precision wheel bearings and large, solid (no compression) wheels, this technology allows virtually anyone to push a 3,200lbs battery with little effort.

Its single-pin steering mechanism makes the BTM operate like a hand pallet truck, and the compact unit offers convenient waist-high lifting and lowering using hand controls. It also includes an integrated hand pump jack that allows you to raise the roller bed to meet the height of most lift trucks.

The battery compartment is available in two convenient sizes 24” or 36”.

- Hand crank-activated positive braking system (optional): No chain latching is required when loading a battery into a lift truck. When the brake is engaged, there is no possible pushback.

- 3-Point pallet truck design with solid wheels: Extremely easy to turn and move while fully loaded

- Single point push/pull travel allows for tight turning and easy maneuverability

- Hand pallet truck lift mechanism: Convenient waist-high lifting and lowering using hand controls

- Stand-alone compact unit: Does not require a fork truck

- Ratchet crank handle: Protects the operator from injury if crank handle slips

- Battery safety stop for security

Maximum Battery Size: 22.25 W x 40” Long

Max Battery Weight: 3,200 lbs

Battery Connection Type: Chain Hook

Overall length: 58”

Overall Height: 55.5”

Carriage lowered height: 4.25”

Carriage Max Raised Height: 22.25”

Overall Width of 24” battery carriage size: 41”

Overall Width of 36” battery carriage size: 53”

Shipping Weight of 24” battery carriage size: 708 lbs / 322 kg

Shipping Weight of 36” battery carriage size: 778 lbs / 354 kg

BTSE

Battery TUGGER STEPPED

An evolution from our trusted BTE series, the BTSE adds flexibility without compromising performance, safety or durability and has made our tuggers the number-one battery-changing choice for over 35 years.

With a comprehensive array of fitments and options, all BTSE models offer flexible step configurations to suit multiple battery sizes and rollout heights for battery capacities up to 5,000 lbs and fitted with our reliable 1,800 lbs electromagnetic extraction system.

Engineered with fully welded uni-body construction and finished in a premium acid-resistant powder coating, the BTSE utilizes the same powerful and reliable electromagnet extraction system as our man aboard systems to deliver smooth, reliable and damage-free battery changes.

- Automatic time-out on magnet ensures long service life and protects against excess discharge on host truck battery

- Simplified maintenance and spare parts to deliver years of hassle-free service

- One-year product warranty and five-year warranty on the magnet only

- Built to last with robust unibody construction and finished in acid resistant powder coating

- Available in 12V,24V, 36V, 48V & 80V configurations to suit common host truck applications

- Wide range of standard widths (30” 36” 42” & 48”) with a full range of step heights and widths to ensure a perfect fit for your battery fleet

- Up to 5,000 lbs battery capacity (depending on host truck capacity)

- Powerful 1,800 lbs electromagnet extraction for safe, quick and reliable changes

- Forward and reverse travel limits switches allow less stress on equipment

- Lead rollers to smooth roll-out transition and reduce stress and damage on vital components

OPTIONS:

- Available in 12V, 24V, 36V, 48V & 80V configurations

- Flexible host truck mounting options including a modification-free option

- Custom control panels and joystick to suit different host trucks and operations

- Optional battery guides allow for handling of smaller pallet truck batteries safely

- 10-pole magnet for batteries over 3,530 lbs

BTSE

Battery TUGGER STEPPED

An evolution from our trusted BTE series, the BTSE adds flexibility without compromising performance, safety or durability and has made our tuggers the number-one battery-changing choice for over 35 years.

With a comprehensive array of fitments and options, all BTSE models offer flexible step configurations to suit multiple battery sizes and rollout heights for battery capacities up to 5,000 lbs and fitted with our reliable 1,800 lbs electromagnetic extraction system.

Engineered with fully welded uni-body construction and finished in a premium acid-resistant powder coating, the BTSE utilizes the same powerful and reliable electromagnet extraction system as our man aboard systems to deliver smooth, reliable and damage-free battery changes.

-

- Automatic time-out on magnet ensures long service life and protects against excess discharge on host truck battery

- Simplified maintenance and spare parts to deliver years of hassle-free service

- One-year product warranty and five-year warranty on the magnet only

- Built to last with robust unibody construction and finished in acid resistant powder coating

- Available in 12V,24V, 36V, 48V & 80V configurations to suit common host truck applications

- Wide range of standard widths (30” 36” 42” & 48”) with a full range of step heights and widths to ensure a perfect fit for your battery fleet

- Up to 5,000 lbs battery capacity (depending on host truck capacity)

- Powerful 1,800 lbs electromagnet extraction for safe, quick and reliable changes

- Forward and reverse travel limits switches allow less stress on equipment

- Lead rollers to smooth roll-out transition and reduce stress and damage on vital components

OPTIONS:

- Available in 12V, 24V, 36V, 48V & 80V configurations

- Flexible host truck mounting options including a modification-free option

- Custom control panels and joystick to suit different host trucks and operations

- Optional battery guides allow for handling of smaller pallet truck batteries safely

- 10-pole magnet for batteries over 3,530 lbs

CBTE

COBRA TUGGER

The Cobra Tugger offers a safe and reliable solution for light duty battery changing applications. Mounted on a walkie or forklift, the Cobra Tugger is a simple and cost-effective way to manage low volume change requirements with a capacity of up to 2,300 lbs.

Combined with a fully electric drive system and a powerful 900 lbs electromagnet extraction, the Cobra Tugger has the same rugged uni-body construction as the BTE series and is equipped with many of the technologies employed on our larger units, including tough battery sliders, added safety features and innovative slider bed design. The low-profile design and simple user controls allow operators to quickly and effectively perform changes in a safe manner.

- Built to last with robust unibody construction

- Finished in acid-resistant powder coating

- Flexible host truck mounting options

- Complete electrical system ensures low lifetime cost of ownership

- Powerful 4 pole 900lb capacity electromagnet extraction system for quick and reliable change

- Lead rollers smooth the roll-out transition, reducing stress and damage to vital components

- Suited for lighter-duty applications

- 2,300 lbs capacity

EZ-Tugger

Easy TUGGER

Optimal for small operations the CBH’s EZ-Tugger is the perfect budget friendly battery changing solution. Designed for batteries weighing less than 2300 lbs the EZ-Tugger is ideal for small fleets. A stand-alone unit, permanently welded onto an industry standard hand pallet jack making it small, portable and easy-to-use. It carries a built-in charger and battery used to power the electromagnet and push/pull mechanism.

All extraction functions are push button and electrically powered, limiting the operators contact with the battery. The EZ-Tugger operates similarly to a standard pallet jack, making it easy to implement into any small-scale operation. With minimal required maintenance and few moving parts, the EZ-Tugger is designed to stand up to the harsh environments of todays battery rooms.

- Powerful 4-pole (900 lbs capacity) electromagnet push/pull mechanism improves change speed and substantially reduces the risk of injuries to the operator

- A positive braking system prevents push-back during battery change, eliminating the need for retaining chains

- An integrated hand pallet jack provides the operator with an industry-standard machine that is easy to maneuver

- Slider bed design restrains the battery automatically, requires no maintenance, and eliminates the need for a time-consuming and fragile battery restraint system

- Built-in battery and charger allow for recharging of the on-board battery anywhere household current is available

- 2,300 lbs capacity

- OPTIONS:

- AC power supply – 120 volt AC

- Custom color options

- 5 year magnet warranty

- Extended warranty & service program 2-5 year

- Lifting range 6.5″ – 10.25″

EZ-Tugger

Easy TUGGER

Optimal for small operations the CBH’s EZ-Tugger is the perfect budget friendly battery changing solution. Designed for batteries weighing less than 2300 lbs the EZ-Tugger is ideal for small fleets. A stand-alone unit, permanently welded onto an industry standard hand pallet jack making it small, portable and easy-to-use. It carries a built-in charger and battery used to power the electromagnet and push/pull mechanism.

All extraction functions are push button and electrically powered, limiting the operators contact with the battery. The EZ-Tugger operates similarly to a standard pallet jack, making it easy to implement into any small-scale operation. With minimal required maintenance and few moving parts, the EZ-Tugger is designed to stand up to the harsh environments of todays battery rooms.

-

- Powerful 4-pole (900 lbs capacity) electromagnet push/pull mechanism improves change speed and substantially reduces the risk of injuries to the operator

- A positive braking system prevents push-back during battery change, eliminating the need for retaining chains

- An integrated hand pallet jack provides the operator with an industry-standard machine that is easy to maneuver

- Slider bed design restrains the battery automatically, requires no maintenance, and eliminates the need for a time-consuming and fragile battery restraint system

- Built-in battery and charger allow for recharging of the on-board battery anywhere household current is available

- 2,300 lbs capacity

- OPTIONS:

- AC power supply – 120 volt AC

- Custom color options

- 5 year magnet warranty

- Extended warranty & service program 2-5 year

- Lifting range 6.5″ – 10.25″

Get in Touch

Office: 1 (905) 564-0303

Toll Free: 1 (866) THE-BULL

Fax: 1 (905) 564.0313

sales@carneybatteryhandling.com

Open Hours

Monday – Friday: 8:00 am – 4:30 pm

Our Office

14 Regan Road, Unit 2A

Brampton, Ontario

L7A 1B9 Canada