ABM

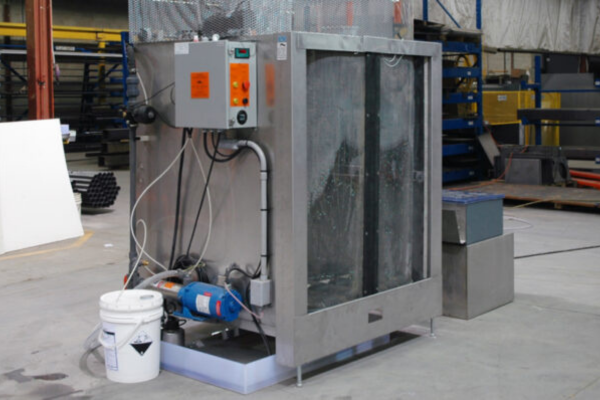

AUTOMATIC BATTERY MAID

It is well documented that a clean battery dramatically improves lift truck performance by reducing voltage drops, ground tracking and corrosion to both the battery and lift truck, as well as providing increased safety for both operators and maintenance personnel.

Carney’s ABM allows you to enjoy these benefits without the usual risk and mess associated with traditional pressure cleaning and manual battery wash stations. The automated wash and drying features are housed within a self-contained unit that is user-friendly and simple to use.

This stand-alone unit can be connected to our Wastewater Treatment System (WWTS) to provide a closed-loop battery washing system that does not require drainage.

- All stainless-steel construction for maximum corrosion resistance and durability

- Standard powered door with option of automated door system

- Flip top allows for both roll-out and lift-out battery applications

- Highest flow rate (16GPM) and wash pressure (100PSI) available

- Powered oscillating wash arm is adjustable to suit all battery widths and sizes

- Comprehensive safety systems include full door interlock during use, safety guards on external pinch points, ground fault indication.

- Programmable wash time and drying time to suit your fleet and schedules

- Clear digital pH meter and automated neutralization

- Full range of matched consumables

- Can be integrated to our Wastewater Treatment System (WWTS)

- Fully compliant with strict environmental regulations for battery washing

OPTIONS:

- Wastewater System

- Battery Shine Wash Solution

- Magic Powder Flocculent

- Filter Media Kits

- Air Compressor Kits

BWS

Battery WASH SYSTEM

For small fleets with infrequent washing needs, CBH’s semi-automatic wash station provides an efficient and cost effective to keep your batteries operating at their peak. The BWS allows for both roll-out and lift-out systems with a full range of matched consumables and can be integrated with our Wastewater Treatment System (WWTS) to provide a closed-loop battery washing system that does not require drainage.

- Heavy-duty stainless-steel construction

- Independent 1700 PSI supply delivered via handheld wand

- Digital PH display which automatically dispenses neutralizer

- Suits roll-in or gantry loading of batteries

- No floor drains required

- Integrated splash guards

- Ground fault circuit protection

- Adjustable legs for leveling

OPTIONS:

- Wastewater System integration

BWS

Battery WASH SYSTEM

For small fleets with infrequent washing needs, CBH’s semi-automatic wash station provides an efficient and cost effective to keep your batteries operating at their peak. The BWS allows for both roll-out and lift-out systems with a full range of matched consumables and can be integrated with our Wastewater Treatment System (WWTS) to provide a closed-loop battery washing system that does not require drainage.

- Heavy-duty stainless-steel construction

- Independent 1700 PSI supply delivered via handheld wand

- Digital PH display which automatically dispenses neutralizer

- Suits roll-in or gantry loading of batteries

- No floor drains required

- Integrated splash guards

- Ground fault circuit protection

- Adjustable legs for leveling

OPTIONS:

- Wastewater System integration

PBWS

PORTABLE BATTERY WASH STATION

For all your portable battery washing needs, CBH’s portable battery wash station provides an efficient and cost-effective way to quickly keep your batteries operating anywhere. The PBWS is outfitted with a 1700 PSI pressure washer & removable trash tray for convenient & easy cleaning. Extremely compact, the PBWS allows for drastically reduced downtime, creating more value for mobile service providers.

- Extremely compact for easy handling and transporting

- 100% stainless steel and PVC construction for long life

- Removable slide strips for easy access

- Stainless steel sump pump lifts out for easy cleaning

- Removable trash screen for easy cleaning

- Clear removable PVC splash curtain for easy access

- Two removable top covers help to prevent overspray

- Compact fold down operator standing platforms

- Two on-board, 150 gal. water holding tanks

- Ground fault protected electrical outlets

- Minimal over-spray during operation

- Integrated 1600 PSI pressure washer with spray nozzle and brush

- ½ HP wastewater discharge pump

OPTIONS:

- Remote Management Interfaces for offsite management and control

- Integrated Battery Management Systems to optimize battery performance and life

- Overall length 87”

- Overall width 57”

- Overall height 62”

- Total weight 854 lbs.

- Power requirements: 120 V/ @20 amps

- 1600 PSI @ 1.23 gal. per minute

- Total amp draw of 16 amps @ 120V

WWTS

WASTEWATER TREATMENT SYSTEM

With an increased focus on both environmental impact and safety practices in today’s workplace, the handling and disposing of hazardous waste by-products from battery washing can be a complicated and expensive task.

Our Wastewater Treatment System (WWTS) allows for fast, easy, safe and most importantly, environmentally friendly handling and disposal of your battery washing contaminates.

Engineered and constructed as a stand-alone unit, the WWTS works directly with our Automated Battery Maid (ABM), however it can be modified to accommodate any battery wash system in your facility.

The WWTS provided a clean ‘white glove’ approach to handling and managing the contaminants by preventing them from re-entering the environment, separating contaminants into a filtered tank for removal and disposal while reclaiming <98% of the water for re-use.

- Freestanding closed-loop construction with no need for floor drains or other outlets

- 98% of water can be reclaimed and reused

- Will filter and recycle water within minutes for reuse in wash systems

- Clear PVC body makes operation and management of supply a breeze

- Hinged lid systems for clean handling

- Integrated control system when used with our Battery Maid

- Low water supply cut-off protects pump from excess wear and stress

OPTIONS:

- Magic Powder Flocculent

- Filter Media Kits

WWTS

WASTEWATER TREATMENT SYSTEM

With an increased focus on both environmental impact and safety practices in today’s workplace, the handling and disposing of hazardous waste by-products from battery washing can be a complicated and expensive task.

Our Wastewater Treatment System (WWTS) allows for fast, easy, safe and most importantly, environmentally friendly handling and disposal of your battery washing contaminates.

Engineered and constructed as a stand-alone unit, the WWTS works directly with our Automated Battery Maid (ABM), however it can be modified to accommodate any battery wash system in your facility.

The WWTS provided a clean ‘white glove’ approach to handling and managing the contaminants by preventing them from re-entering the environment, separating contaminants into a filtered tank for removal and disposal while reclaiming <98% of the water for re-use.

- Freestanding closed-loop construction with no need for floor drains or other outlets

- 98% of water can be reclaimed and reused

- Will filter and recycle water within minutes for reuse in wash systems

- Clear PVC body makes operation and management of supply a breeze

- Hinged lid systems for clean handling

- Integrated control system when used with our Battery Maid

- Low water supply cut-off protects pump from excess wear and stress

OPTIONS:

- Magic Powder Flocculent

- Filter Media Kits

WASHING CONSUMABLES

AVAILABLE THROUGH CBH

Safe and effective washing of your battery assets can only be achieved using the right consumables. CBH offers a complete line of washing consumables to allow fast, accurate and efficient cleaning without mess, including Battery Shine Cleaning Solution, Magic Powder Flocculant and Filter Media.

Battery Shine (CBS-250)

- Non foaming de-greasing agent neutralizes acid deposits and buildup

- Breaks down

- Accelerates settling process in waste treatment

“Magic Powder” Flocculant Formula (ST-901)

- Accelerates settling and separation in Wastewater Treatment System (WWTS) allows for white glove disposal

Filter Media 50/100 Sheet Packs (ST-900/914)

- Replacement filter media for Wastewater Treatment System (WWTS)

Get in Touch

Office: 1 (905) 564-0303

Toll Free: 1 (866) THE-BULL

Fax: 1 (905) 564.0313

sales@carneybatteryhandling.com

Open Hours

Mon – Fri: 8:00 am – 4:30 pm

Our Office

14 Regan Road, Unit 2A

Brampton, Ontario

L7A 1B9 Canada