If you’re responsible for managing a battery room, you know how important it is to protect your investment in forklift batteries. But it’s also crucial not to overlook the value of the equipment that charges those batteries. After all, a damaged charger can be a significant financial setback, with battery chargers in 2023 ranging from $400 to $3200 per unit.

1. Invest in the right equipment!

Standard shelving won’t cut it in a battery room, where electrolyte leaks and forklift collisions can easily damage equipment. Instead, consider investing in custom-designed charger stands from a reputable manufacturer. CBH stands are built to withstand the unique challenges of a battery room environment, with heavy-duty construction and customizable configurations to accommodate your chargers.

2. Calculate charging costs

The cost of ownership for forklifts goes beyond the purchase price. Take the time to calculate your charging, operating and energy costs and select a battery room configuration that supports your budget/needs.

The energy costs per battery can be calculated by multiplying the power use (in kilowatts per hour, kWh) by the number of hours needed to charge. Multiply that value by the cost per kWh.

3. Protect cables from damage

Charging cables are the most vulnerable part of a battery charger, and they’re often subject to kinks and pinches over time. This can lead to uneven charging and ultimately damage to the charger. To prevent this, it’s important to develop a strong cable management strategy. Consider using cable retractors, pogo sticks or wall mount brackets to keep cables stored safely out of the path of lift trucks.

4. Follow the mounting protocols

Proper mounting is essential to ensure that your chargers stay securely in place, even in the event of a collision. Be sure to use stands that are designed specifically for the type of charger you’re using and mount them firmly in place using all four corners. If possible, choose stands that are easy to assemble to make installation easier.

5. Install structural barriers

Even with proper training and safety protocols, accidents can happen in a busy battery room. Consider installing heavy-duty guardrails and bollards around charger storage areas to prevent forklift collisions from damaging your charger collection. These structural barriers are designed to withstand impact forces and can help you comply with important OSHA regulations.

By following these best practices, you can ensure that your forklift fleet provides reliable service for years to come while meeting your budget for 2024. Here are just a few of the charger stands we offer:

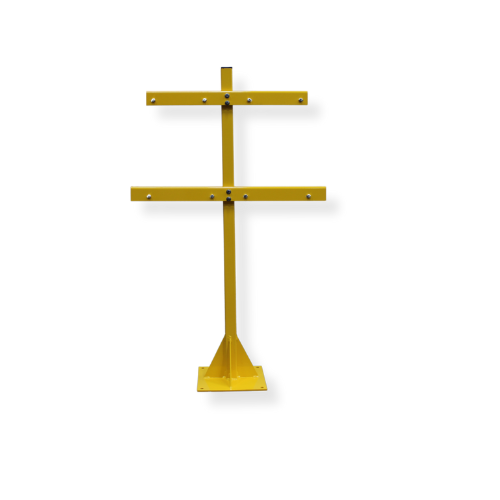

Universal Charger Stand

The Universal Charger Stand or UNI-Stand is precisely designed to accommodate multiple chargers of any type. Simply assemble it, attach your charger of choice and charge.

Eclipse Charger Stand

CBH Park & charge stand comes with 2 shelves positioned both at the front or on the opposite sides, perfect for in-truck park and charge applications.

Powerforce Charger Stand

These stands are designed for high-frequency charging. Expertly crafted with bolt-on shelving, durable powder coating and custom color choices.

Versa Charger Stand

With two simple supports that attach to the sides of any charger the Versa Stand is constructed of powder coated heavy-duty steel. The compact design saves space and makes it the most affordable unit on the market.

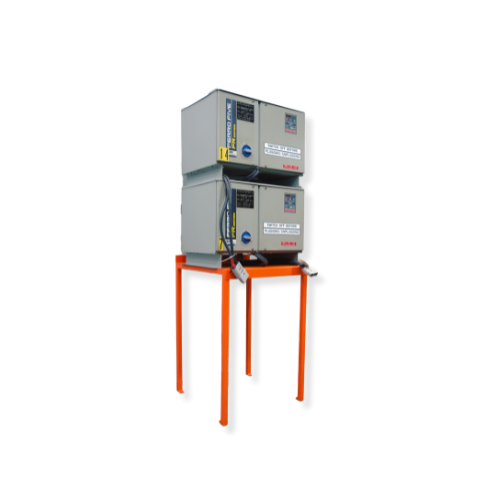

Floor Mount Charger Shelves

Floor-mounted charger shelves are perfect for larger/heavier chargers and are easily coupled with roller stands for an all-in-one charging solution that integrates seamlessly into your battery room.

Charging Accessories

Mounting accessories are crucial to every charging setup, CBH offers lift truck stops, wall mount charger brackets, cable retractors and pogo sticks.