As the electric forklift industry evolves, new battery chemistries and high-frequency chargers present unique challenges for distribution centers. While manually changing batteries is still a valid option for many high-volume companies, parking and charging forklifts is becoming the new normal. Having a dedicated park and charge area is affordable and helps your operation perform efficiently.

Over the years, Carney Battery Handling has found the secret to battery changing. Whether your warehouse operates using fast, opportunity, or conventional charging, the key to an efficient charging area is preplanning.

Planning is essential as it streamlines organization and ensures priorities are clear. Preplanning will boost productivity, create competitive advantages, and ultimately improve warehouse organization.

Here are four basic questions to ask when preplanning your charging space:

That’s not all; here are nine tips for designing a park and charge area.

Consider the truck type and the space required for each unit.

Grouping similar truck styles

Grouping similar truck styles promote efficiency in your warehouse and allow the AC amp draw of those chargers to be organized in the same area.

Determine how much power is required

Anticipate extra power for panelboards

Panelboards that supply power for the park and charge area should accommodate 20% more than the anticipated maximum power use of all the chargers connected to the panel.

Anticipate extra power for circuit breakers

Circuit breakers inside the panels should accommodate 20% more power than the recommended amp rating of the charger.

Be aware of stamped ratings on chargers

Be aware of the two ratings stamped on the chargers, as it will determine the maximum load that the cabinet can handle and the configured load of the accompanying charger.

Example: The cabinet rating can be 50 amps @ 480 VAC with six power modules installed in the cabinet (Max), and you might purchase units with only four modules. The correct configured load is now 33.2 amps.

Choose an optimal location for your charging area

With the calculations set, it is time to work on spacing and location. The battery charging area should be near office stations and breakrooms for convenience when charging is required.

Prepare for power distribution

Look at your building plans. Locating and situating your charging area near your main switchgear is a must. Large fleets can use 2,000 amps of 480. Charging areas will most likely be the area of your warehouse that uses the most power. Wrongful placement can result in additional costs for power distribution.

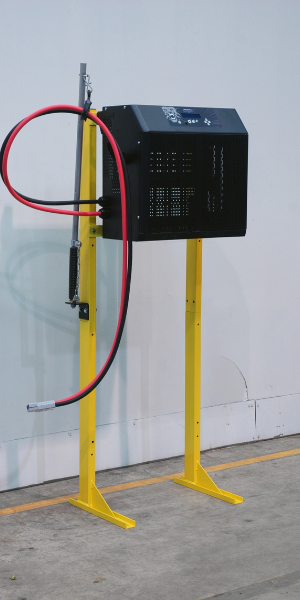

Select the correct charging system