Changing forklift batteries efficiently is a vital component of warehouse operations often overlooked. Implementing warehouse automation for operators affects the bottom line, impacts health & safety, and, if correctly implemented, dramatically affect warehouse flow.

If you take the time to review the operator’s perspective for every battery change, the value of a dedicated battery room or changing system becomes apparent.

How does dedicated battery handling equipment affect warehouse safety?

Traction batteries are HEAVY and usually fall outside the manual handling regulations in most countries. So, there are strict company guidelines on which batteries can be changed manually, which batteries are a ‘2-man change’ and which batteries must be changed using a mobile battery changer.

Not following these guidelines can lead to personal injury, so the rules protect the health & safety of battery operatives and forklift drivers alike. Many warehouse owners encounter some damage to company assets when using manual methods of battery changing. This can include damage to batteries, cable & plugs, battery racks and material handling equipment (MHE). Getting good equipment alignment is not always straightforward, leading to these damages.

What does downtime mean for your forklift operators?

Changing batteries in the MHE fleet is essential for running extended or multi-shift operations. Forklift productivity stops when it leaves the workstation to when it returns with a fresh battery. Carrying out a ‘2-man change’ can sometimes delay getting the battery changed as forklift operators wait for a colleague to assist. The use of the mobile battery changer is restricted to trained personnel and usually involves waiting.

In addition to the loss of truck productivity, you have the cost of the truck driver and battery room operator to consider. Not having dedicated changing equipment means that employees waste time, impacting throughput.

Is there a safer, quicker way to change batteries that also reduces the size of the battery room?

Yes, warehouse and manufacturing space is expensive, so focus on reducing the space you need to devote to your battery charging room. Today, new construction warehouses often have internal heights of 10m or more to utilize high-level storage. It makes sense to adopt a similar approach with your battery-changing system. Install multi-level battery storage & charging racks that will release valuable floor space for use by your core business, which will reduce your battery room size by as much as 70%.

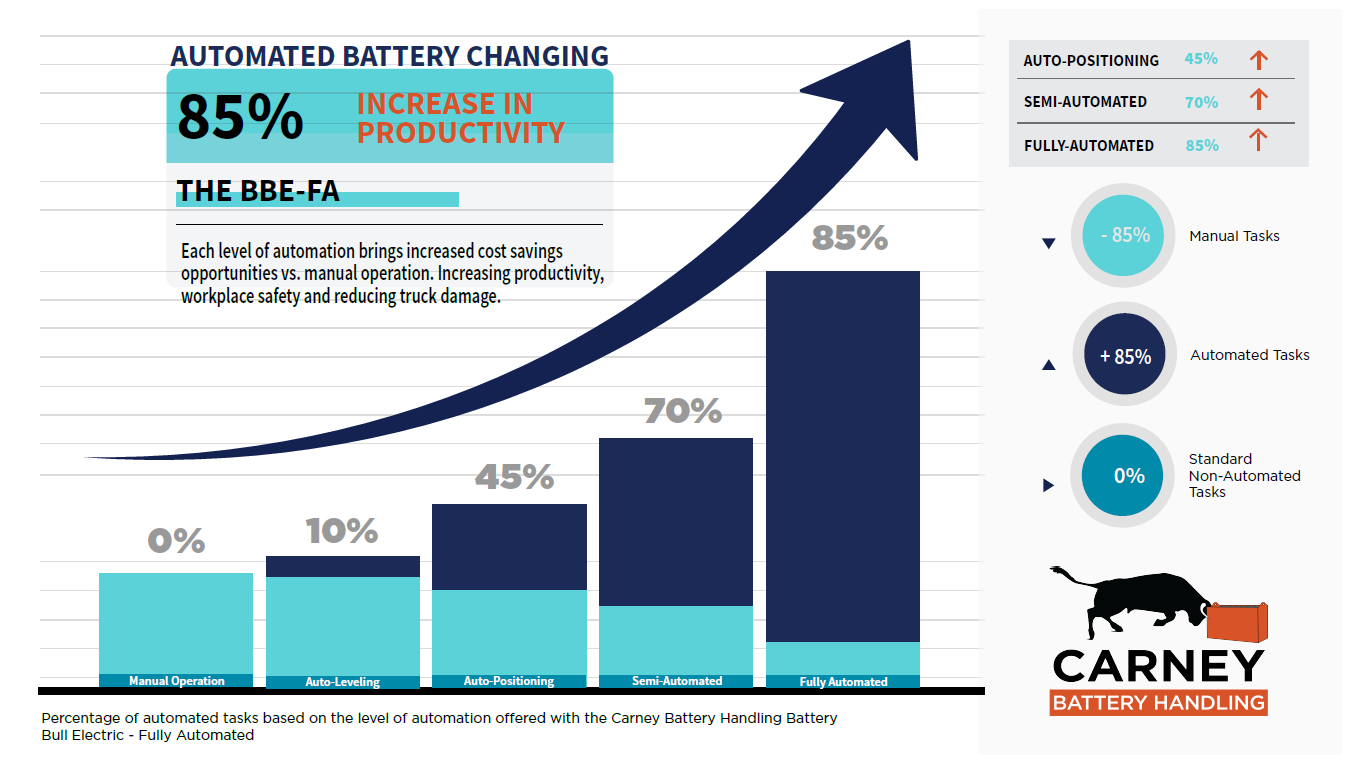

What is a fully automated battery changing system?

So-called ‘fully automated’ systems appear in many guises on the market. Some claim to be fully automated, but only certain aspects are automatic; they still rely on having an operator on the machine to perform specific functions – which is taxing for operators and frankly wastes valuable time. If you compare this to the automotive sector, you buy an ‘automatic car,’ but the only mechanical part is the gearbox; OK, you can add in cruise control, but you still need a driver to steer the vehicle and avoid hazards. We all understand automobiles but do many of us know about battery changing? It is essential to understand the functionality of your buying product and match it with the benefits you require.

A truly Fully automated system like the CBH BBE-FA operates completely driverless – as a proper automated system should; in fact, the forklift driver whose battery is being changed stands on a pressure mat many meters away from the battery changing operation once he has prepared his forklift for a battery change.

Take a look at the battery-changing flowchart and the productivity impact….

The truth is, operators, benefit just as much from automated battery handling as your business does. It saves forklift drivers time, keeps them safe and streamlines the workday so that operators can better utilize their time where it counts for business growth. It’s an investment but well worth it for businesses that want to reduce downtime, improve warehouse safety, and increase employee retention.

Visit our YouTube Channel and check out the BBE-FA video: https://youtu.be/uxYy6VSEBac

Very well stated John. The clarity in your post will definitely help in the decision making of anyone who may be considering automation for their battery handling operation.

Thanks