Fully automated battery changing is now a reality

So if you run a business that has a fleet of electric material handling equipment (MHE) such as pallet trucks, order pickers, reach trucks and forklifts and operate a multi-shift work pattern, you are familiar with the need for efficient battery changing during an average work day.

The questions is, why haven’t you automated the process? If you didn’t realize this was something that could be automated, then we have news for you….

You may recognize the following scenarios

There are several methods of changing batteries in electric MHE; manually changing batteries using 1 or 2 members of staff and a lot of brute strength, powered mobile changers using magnets or vacuum cups, right through to man-aboard battery transfer carts. All these methods have a degree of human interaction to achieve a battery change and can take anywhere from 5 to 15 minutes to complete.

The industry is shifting from manual changing methods to automation as manual changing is incredibly labor intensive and comes with inherent risk to the operators’ health & safety. In general, battery changing equipment with power assisted pulling/pushing is the preferred option.

The more you invest in battery changing equipment, the safer and quicker the battery change becomes. However, you still need dedicated, well trained staff to execute safe battery changes, and, in the case of large fleets with a battery transfer cart, you need a dedicated operator round the clock.

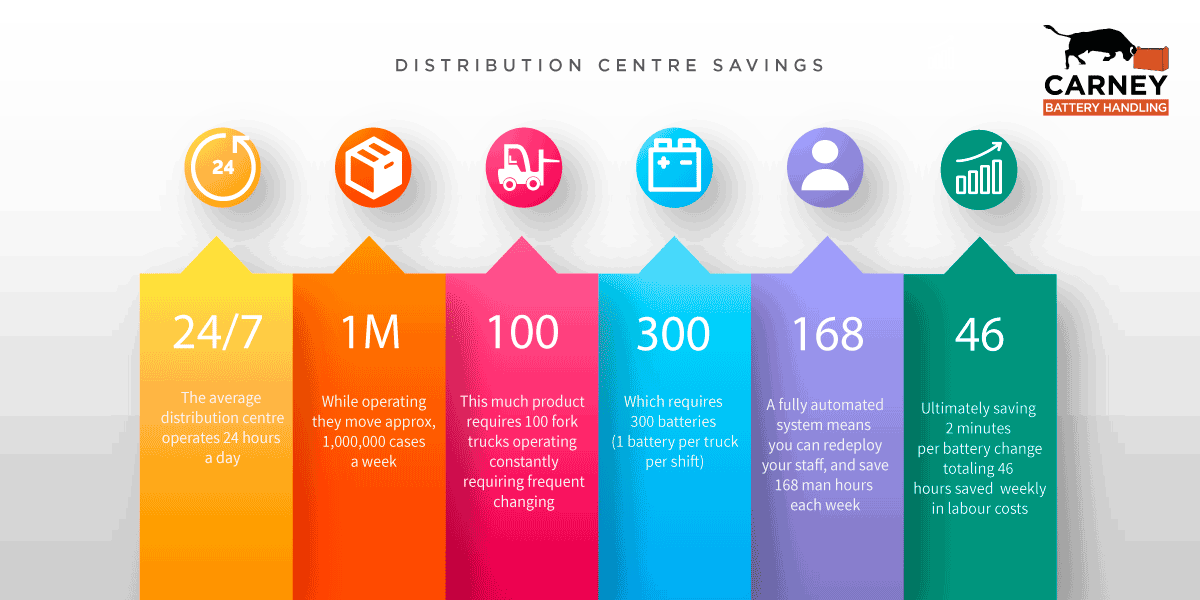

A fully automated battery change system will appeal to users who want to bring efficiencies and consistency to their business and make their workplace a safer environment for their MHE operators. If you are more interested in Return On Investment (ROI) and Total Cost of Ownership (TCO) than the initial price tag then these key features will grab your interest:

- No human intervention needed in the battery change process creates a safer working environment and releases dedicated operators for redeployment

- Precise changing drastically reduces damage to MHE, batteries and charging racks

- Fast battery changes (typically 3-4 minutes) reduce truck downtime

- Overall productivity of the MHE fleet increases

Overall, the proper material handling equipment setup for your business is crucial for optimal performance, contact our sales team for a detailed quote customized to help you meet the demand.