With labour costs continuing to climb and managers challenged to effectively track and manage their fleet, those who’ve chosen to invest in automatic battery-changing equipment like the Mini Auto Changer are in for some seriously innovative upgrades.

First designed in 2004, the “mini” auto changer was developed for Miller Coors in Georgia. Fully automated but compact, the MAC provides fully automated changing for smaller fleets. Since then, the system has evolved; here are the latest product improvements and updates.

Optional Lift

Now equipped to lift above one level, the MAC can support Automatic Guided Vehicles or AGVs with different roll-off heights and can support mixed fleets.

Remote Monitoring

Every Automatic Changer manufactured by Carney now comes with a remote access module which allows Carney to keep systems updated and provide immediate assistance from anywhere.

IO-Link

All MAC analog position sensors have been upgraded to IO-Link or smart sensors. The measurements of these new sensors are converted into digital values before transmission. Compared to analog signals, these signals are far less susceptible to interference. This translates into more precise positioning and control. Another advantage to IO-Link is seamless and simple sensor replacement. The device configuration is stored in the IO-Link master so an operator can simply swap the sensor, and the correct device configuration is automatically loaded.

The next generation of Omron HMI (Human Machine Interface) 12.1-inch wide screen enables faster and more efficient control and monitoring. Our new interface is programmed intuitively for easy operation and equipment maintenance. The customized battery bay overview screen allows quick real-time updates on the state of all the batteries in your racks, and an optional 50-inch screen allows you to view the rack status from far away.

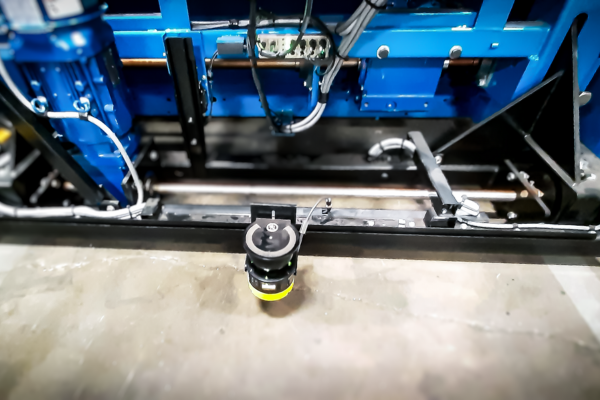

Safety Scanners

The new Sick scanners provide additional zones for slowing down and stopping control. “This new microscan3 offers advantages thanks to safeHDDM scanning technology. safeHDDM® is based on the HDDM (HDDM = high-definition distance measurement) process, which has been proven in practice many times over, and is setting a new benchmark in the evaluation of optical time-of-flight measurements. The patented process developed by SICK delivers unique measurement results for safety laser scanners by filtering and evaluating many individual pulses. In this way, safeHDDM® enables very high resistance to dirt, dust, and ambient light. The most important part: safeHDDM® retains its reliability. Even an object with a remission factor of just 1.8%, for example, black suit pants, is reliably detected by the safety laser scanner.”

Product highlights:

- Latest hardware in automation with an intuitive touchscreen for control and monitoring

- Self-diagnostics that significantly decrease downtime and servicing, which maximizes production time.

- Safety PLC to monitor safety scanners and drives.

- Ultra-low maintenance requiring service every 300 hours.

Read more about the MAC here.

Contact us: sales@carneybatteryhandling.com

Park & Charge Stands

Carney Battery Handling offers a wide range of park and charge stands to suit multiple charger configurations suited to various facility layouts. Our opportunity charging stations and floor mount charger shelves can be completely customized for various widths, heights and shelves and shelf configurations.

The Battery Bull Electric - Fully Automated

Powerful, compact and energy-efficient PLC-controlled Variable Frequency Drives (VFD) are coupled with electric gearboxes to provide simultaneous power to lift and drive functions. The BBE-FA is one of the few high-volume fully electric transfer cart options and can be completely automated.