Properly caring for your forklift batteries lengthens their lifespan; the question is, what upkeep is required to achieve longevity for your batteries, and how often should you do it?

Forklift batteries need to be maintained to protect the operator, battery, and forklift from unnecessary breakdowns and damage. The electrolytes found in batteries are composed of deionized water and sulphuric acid. When water levels get low, battery electrolytes oxidize, shortening battery life and reducing charging capacity indefinitely. This oxidization can build up on the batteries and needs to be removed with frequent watering and washing; typically, batteries should be washed once monthly, but this may vary if working conditions are squalid.

Consistently Washing Your Forklift Batteries Can:

- Prevent acid and residue build-up

- Reduce voltage drop

- Increase the cycle life of batteries

- Minimize heat build-up during the charging cycle

- Reduce maintenance requirements for batteries, trucks, and chargers

- Minimize corrosion

- Produce longer run times per charge

- Optimize truck operation

If left unwashed, the electrolyte residue omitted by lead-acid batteries can create a conductive environment resulting in frequent discharge, which interferes with the battery’s chemistry and causes it to charge improperly. This process will limit the battery’s lifespan inflating operational costs, damaging charging terminals, and increasing the risk of operator injury. Keep your batteries watered by following the tips listed below.

Tips For Watering Your Forklift Batteries:

- Use de-ionized, clean water

- Ensure the water covers the battery element (always top-up batteries in accordance with the manufacturers’ instructions’

- Water batteries after charging

- Consider implementing a battery washing station or integrating a complete washing system.

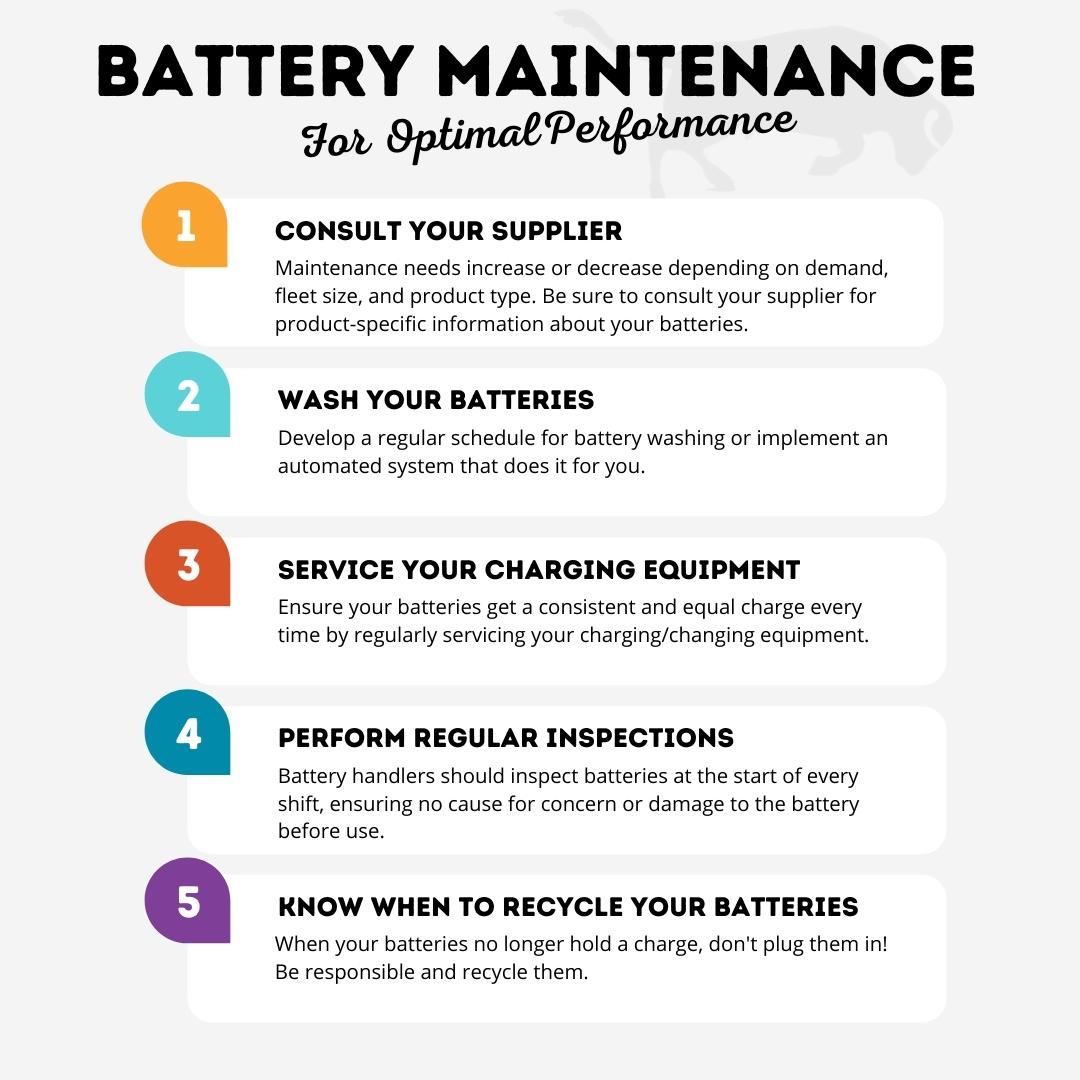

Maintenance Tips To Ensure Your Fleet Is Performing At Its Best:

Even with regular maintenance and precautions, battery handlers are exposed to dangerous chemicals and fumes. Take precautions and ensure your maintenance team is outfitted with OSHA-approved personal protective equipment while maintaining your forklift fleet. This list of equipment should include:

- HAZ-MAT boots

- Acid-proof gloves

- Splash shield

- Apron

- Goggles

Battery room staff should always wear PPE and follow the handling guidelines standardized by OSHA. For an entire list of recommended procedures and mandated policies, visit the OSHA website here.

Clean batteries dramatically improve lift truck performance by reducing voltage drops, ground tracking, and corrosion. Automatic or portable battery wash systems allow you to enjoy the benefits of battery washing without the usual risk and mess associated with traditional pressure cleaning. Every fleet will require different maintenance depending on battery type, fleet size, changing frequency, charging frequency, etc. Here are some battery room add-ons to maintain your assets.

Automatic Battery Maid

Carney’s ABM allows you to enjoy these benefits without the usual risk and mess associated with traditional pressure cleaning and manual battery wash stations. The automated wash and drying features are housed within a self-contained unit that is user-friendly and simple to use.

Portable Washing Station

For all your portable battery washing needs, CBH’s mobile battery wash station provides an efficient and cost-effective way to keep your batteries operating anywhere quickly.

Waste Water Treatment

Engineered and constructed as a stand-alone unit, the WWTS works directly with our Automated Battery Maid (ABM). However, it can be modified to accommodate any battery wash system in your facility.