by John Lawton | Aug 17, 2022 | Operations, Safety, Warehouse Equipment

Today we look at five essential battery room accessories that are often an afterthought or even overlooked altogether: Conventional ‘flooded’ lead acid forklift batteries contain sulphuric acid. Although in a semi-dilute state, sulphuric acid is still...

by Jim Lane | Apr 13, 2022 | Operations, Productivity, Products, Safety

Let’s discuss how battery handling can protect your forklift fleet. As batteries age, they typically use more water and need to be cleaned more often to remove corrosion and other debris that can cause low voltage drainage, even when not in use. Because of this, many...

by Carney Battery Handling | Feb 17, 2021 | Automation

Written by John Lawton and James Lane Carney Battery Handling Ltd. (CBH) has developed a fully automated battery change system for mainstream material handling equipment. Based on a long pedigree of automated battery change solutions for automated guided vehicles...

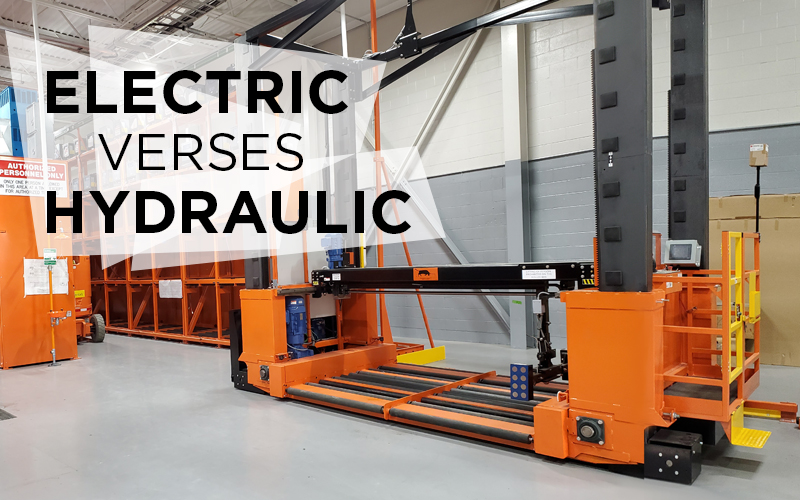

by Jim Lane | Oct 15, 2019 | Productivity, Products

In the battery handling industry, the topic of electric verses hydraulic comes up almost every day. We are always talking to customers about replacing older machines and then we need to explain the operational differences between these technologies. We typically start...