Understanding how to correctly manage your forklift fleet – from energy and airflow to floor space and parking is critical to designing and maintaining an efficient battery room that meets performance goals and provides undeniable returns.

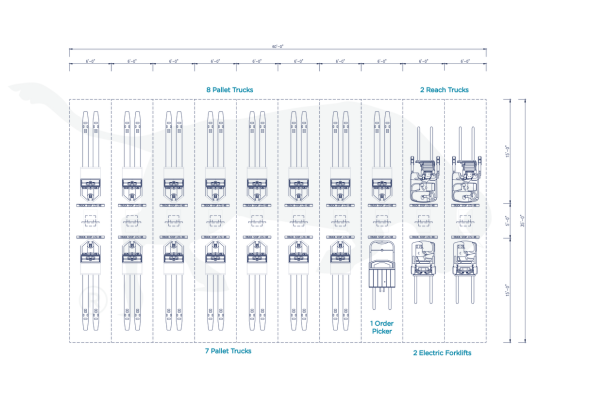

So let’s get hypothetical, you’ve chosen to open a new Distribution Centre to fulfill the ongoing retail needs of various local supermarkets. Are you running it 24/7? I guess you know that each piece of Material Handling Equipment will run on batteries? If so, what kind? How many forklifts, reach trucks and pallet trucks are in your fleet?

These are important considerations. So let’s start at the beginning. How many trucks will run each shift? Once you’ve answered that, you can begin the design process. At this stage, it is vital to determine how much space you can dedicate to each truck and battery.

For example, a stacked system is the best choice if your distribution centre operates 24/7 and the same trucks are reused for every shift. If your fleet has enough trucks to provide a new one to each operator at the start of every shift, Park & Charge is the best choice.

The Park & Charge Area below is for a small distribution centre in Memphis Tennessee with just 20 trucks. This customer chose a battery handling system for low-volume changing and charging because their fleet was not large enough for a fully electric man-aboard battery changing system.

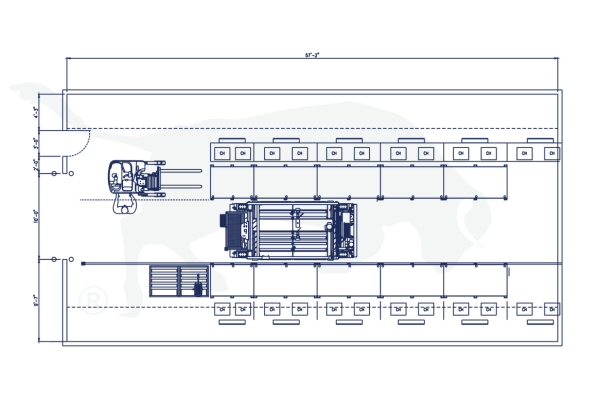

This one, however, has a man-aboard, fully electric retrieval system (The Battery Bull Electric) in place, accompanied by stand-ups on charge on the alternating side. This customer out of Missouri completely reconfigured its battery handling capabilities to store as many batteries as possible while planning for expansion. Both of these battery management systems improve ROI on different scales.

In 2022, Modern Material Handling conducted a survey wherein 60% of distribution centres planned to ramp up their spending this year in storage optimization, automation and labour to improve workplace flow for productivity.

Likely because in North America, 80% of warehouses still use manually operated equipment. As a result, DCs in North America have reportedly used 85.6% of their floor space.

If you are part of the 85.6% these tips will help you identify which battery management system works best in your warehouse:

- Know how many batteries need to be stored.

- Ensure power requirements are met in the agreed-upon area.

- Calculate how much space is needed to store the extra batteries. Compare battery dimensions with available racking space before you carve out any area for your battery room.

- Evaluate the area to see if ventilation is required.

- Dedicate a space for battery storage in your DC floor plan.

- Decide whether racking to stack the batteries works best for your operation.

- Batteries contain sulphuric acid. You will need acid-proof paint on the floor, an emergency eyewash station, acid spill kits and PPE.

- Changing each battery depends on the type of trucks used, budget and roll-out height. Get help from an MHE expert.

Regardless of what equipment you think is best, tackling battery management should never be done alone. Work with a team of specialists to discover which equipment works best, provides the best returns, prioritizes safety and fits within your budget.

Contact our sales team, discuss your plans and get a detailed quote for free: sales@carneybatteryhandling.com

The Battery Bull Electric - Fully Automated

Powerful, compact and energy-efficient PLC-controlled Variable Frequency Drives (VFD) are coupled with electric gearboxes to provide simultaneous power to lift and drive functions. The BBE-FA is one of the few high-volume fully electric transfer cart options and can be completely automated.

Park & Charge Stands

Carney Battery Handling offers a wide range of park and charge stands to suit multiple charger configurations suited to various facility layouts. Our opportunity charging stations and floor mount charger shelves can be completely customized for various widths, heights and shelves and shelf configurations.

The Battery Bull Electric

The BBE Series man aboard Battery Bull offers new levels of performance, reliability and safety to support your high-volume and high-density industrial battery change requirements. This product is available as a single-level system, up to a 6-level system. The BBE is the industry’s only fully electric system with no hydraulics, which ensures maximum up-time and minimum maintenance.